Ever been woken up by a strange grinding noise from your laundry room? That sound might mean your washing machine’s drum is in trouble. I’ve faced unexpected appliance repairs before, and it’s really frustrating.

Fixing your washing machine isn’t just about saving money. It’s also about avoiding bigger problems at home. If your washer makes odd sounds or shows wear, it’s important to check if the drum is broken. Catching problems early can save you from a big repair bill.

This guide will help you figure out if your drum has issues. You’ll learn how to spot problems and when to act. Whether you like to fix things yourself or want to be ready, you’ll find useful tips here.

Key Takeaways

- Unusual noises are often the first sign of drum problems

- Visual inspection can reveal critical drum damage

- Not all drum issues require immediate replacement

- Regular maintenance can prevent costly repairs

- Professional assessment is recommended for complex issues

Common Signs of a Broken Washing Machine Drum

Your washing machine sends out signals about its health. Knowing these signs can help you spot drum problems early. Catching drum issues before they get worse can save you money on repairs.

Detecting Unusual Operational Noises

Unusual sounds from your washing machine drum can mean trouble. Listen for these important sounds:

- Loud grinding sounds during spin cycles

- Persistent banging or thumping noises

- Unusual scraping or metal-on-metal sounds

- Rhythmic clicking during machine operation

Identifying Physical Drum Damage

Looking at your washing machine can show you drum problems. Check for:

- Visible cracks or perforations in the drum

- Rust or corrosion marks

- Warped or misaligned drum surfaces

- Loose or damaged internal paddles

Water Leakage Warning Signs

Water around your washing machine is a big warning. Watch for:

- Puddles forming beneath the machine

- Moisture inside the drum after cycles

- Dampness on surrounding floor areas

- Consistent water trails during operation

Spotting these signs early can stop big problems and save you money. Keeping an eye on your washing machine helps it work better for longer.

How to Know If Washing Machine Drum is Broken

Spotting a broken washing machine drum needs careful watching and a detailed check. Your washer’s performance can show signs of drum damage. These signs should not be overlooked.

When you inspect the washing machine drum, look out for these important signs:

- Unusual grinding or scraping noises during operation

- Excessive drum movement or instability

- Visible physical damage or rust

- Unexpected clothing tears or snags

To figure out if your washing machine drum is broken, do these important steps:

- Run a full wash cycle and listen for odd sounds

- Turn the drum by hand to check for smoothness and resistance

- Look inside the drum for sharp edges or loose parts

- Check for rust or corrosion on the drum’s edges

The state of your washing machine drum affects its work. Recurring problems with drum movement or strange noises often mean there’s a mechanical issue that needs fixing right away.

| Symptom | Potential Drum Issue | Recommended Action |

|---|---|---|

| Loud grinding noise | Worn bearings | Professional inspection |

| Excessive drum play | Suspension system failure | Check mounting points |

| Visible drum damage | Structural compromise | Consider drum replacement |

Early spotting of problems through a thorough washing machine drum check can avoid expensive fixes. It also helps your appliance last longer.

Understanding Washing Machine Drum Components

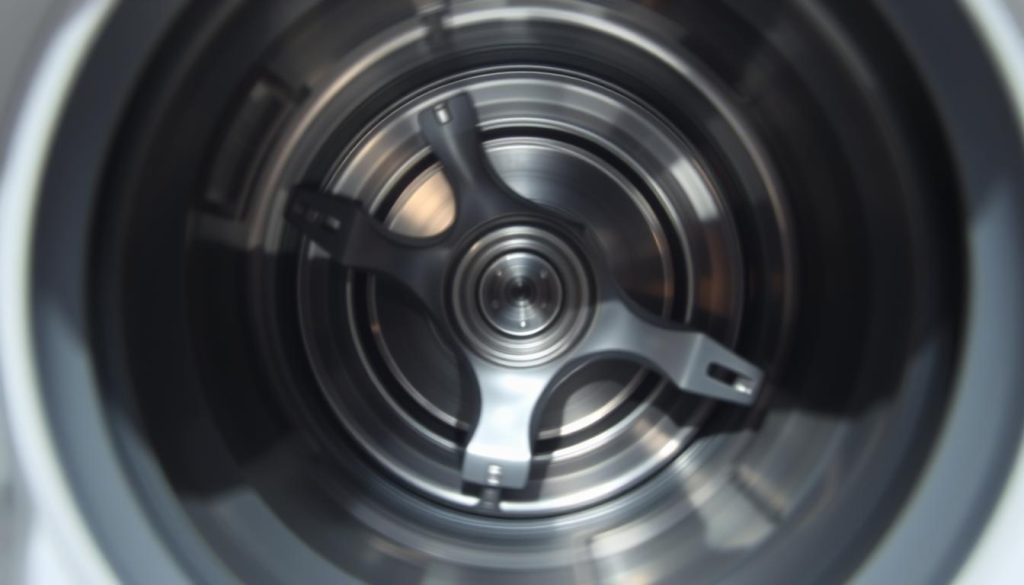

Your washing machine’s drum is made up of many important parts. These parts work together to clean your clothes well. Knowing about these parts can help you find and fix problems.

The inside of a washing machine drum is more complex than you might think. Each part is key to making sure it works right and cleans well.

Drum Bearings: The Rotation Enablers

Drum bearings are the heroes you don’t see. They let the drum spin smoothly during wash and spin cycles. If these bearings get worn out, you might hear grinding sounds, see the drum struggle to move, or feel it vibrate more.

Counter Weights and Balance Rings

These parts are vital for keeping things stable during fast spin cycles. They spread out weight evenly and stop the machine from shaking too much.

| Component | Function | Common Issues |

|---|---|---|

| Counter Weights | Stabilize drum during spinning | Loose mounting, uneven weight distribution |

| Balance Rings | Reduce vibration | Wear and tear, potential cracking |

Paddles and Perforations

The paddles inside the drum mix clothes for a deep clean. Perforations in the drum let water in and out during wash cycles. This makes sure your clothes get cleaned and rinsed right.

Keeping up with maintenance and knowing about these parts can make your washing machine last longer. It also helps you know when you might need a professional to fix it.

Identifying Grinding Noises and Their Causes

Grinding noises from your washing machine are a big warning sign. These sounds are not just annoying. They could mean serious damage that needs fixing right away.

Several key factors can cause washing machine drum noise:

- Worn Bearing Issues: The most common culprit behind grinding sounds is deteriorating drum bearings. As these components wear down, they create friction and produce distinctive grinding noises.

- Foreign Object Interference: Small items like coins, buttons, or jewelry can get trapped between the drum and outer tub, creating scraping or grinding sounds during rotation.

- Damaged Drum Paddles: Loose or broken drum paddles can also generate unusual grinding noises during the wash cycle.

To diagnose the problem, try manually rotating the empty drum. If grinding persists when hand-spinning, you’re likely dealing with bearing damage. Professional inspection becomes crucial at this point to prevent further mechanical breakdown.

Warning: Persistent grinding noises should never be ignored, as they can lead to more extensive and expensive repairs.

Early detection of unusual washing machine drum sounds can save you from costly replacements and extend your appliance’s lifespan. When in doubt, consult a professional appliance technician who can accurately diagnose and resolve the issue.

Inspecting Drum Movement and Stability

Checking your washing machine’s drum is key to keeping it running well. Knowing how to spot drum vibrations can help avoid big problems.

The drum should move smoothly and stay steady. Any odd movement or sounds mean there might be a mechanical problem.

Testing Drum Play

To see if your drum is stable, do this:

- Unplug the washing machine for safety

- Open the door and gently push the drum from top to bottom

- Watch how much it moves

Identifying Loose Components

Loose parts can make your drum vibrate a lot. Look out for these signs:

- Unusual rattling during spin cycles

- Thumping sounds when the drum rotates

- Visible wobbling or uneven movement

Assessing Bearing Condition

| Bearing Condition | Symptoms | Recommended Action |

|---|---|---|

| Healthy Bearings | Smooth rotation, no noise | Continue regular maintenance |

| Worn Bearings | Grinding sounds, resistance | Professional inspection recommended |

| Damaged Bearings | Significant play, loud noises | Immediate repair or replacement |

Pro tip: If you’re not sure about your drum’s condition, get a pro to check it. They can do a full inspection and find any problems.

Common Causes of Drum Damage

Knowing why washing machine drums get damaged can save you money and hassle. Your washing machine’s drum is very important. It needs to be looked after well.

There are a few main reasons why drums get damaged:

- Overloading: Putting too many clothes in one load is hard on the drum and its bearings

- Too much detergent can harm the seals inside

- Things like coins or keys can scratch the drum

- Loads that aren’t balanced can cause the drum to spin unevenly

Keeping your washing machine’s drum in good shape starts with knowing these risks. Always overloading your machine can damage its parts. This might lead to expensive repairs.

“Prevention is always cheaper than repair” – Appliance Maintenance Expert

To keep your washing machine’s drum safe, follow these tips:

- Don’t fill the drum more than 75% full

- Check pockets before washing

- Use the right amount of detergent

- Make sure clothes are spread out in the drum

By following these easy steps, you can make your washing machine last longer. And you’ll avoid drum damage.

When to Check for Trapped Items and Debris

Keeping your washing machine drum clean is more than just a routine task. Sometimes, items in your laundry can hide and cause damage to the drum.

Foreign objects can quietly harm your washing machine’s performance. They often sneak in through pockets and can damage the drum if not found.

Foreign Object Detection Strategies

- Inspect all pockets before loading laundry

- Check clothing for loose buttons, coins, or small items

- Scan the drum’s interior before and after each wash cycle

- Listen for unusual sounds during washing

Impact on Drum Performance

It’s crucial to watch out for foreign objects in your washing machine. Small items like coins or jewelry can scratch the drum, leading to serious damage.

| Object Type | Potential Damage | Recommended Action |

|---|---|---|

| Coins | Surface scratches | Remove immediately |

| Keys | Deep drum scratches | Stop cycle, inspect drum |

| Small toys | Potential mechanical interference | Check drum seal and interior |

Acting quickly can save you from expensive repairs. Simple maintenance can protect your washing machine from wear and tear.

Remember: A few seconds of prevention can save hundreds in repair costs.

Be careful around the drum and door seal, where small items often get stuck. If you hear unusual grinding or tapping sounds, stop the wash cycle right away.

Professional Inspection vs DIY Assessment

Fixing washing machine drums can be hard. Knowing when to fix it yourself and when to get a pro is key. It keeps your machine running well and avoids expensive fixes.

For simple problems, DIY is good. You can spot basic issues by looking closely. Some tasks you can do include:

- Checking for visible drum damage

- Listening for unusual grinding noises

- Detecting minor water leakage

- Removing trapped objects

But, for bigger issues, you need a pro. This is when:

- Internal parts show a lot of wear

- Tests show complex mechanical problems

- Repairs need special technical knowledge

- Safety risks are involved

Experts in washing machine repair have big advantages. They have advanced tools, lots of training, and can find hidden problems. Trying hard repairs without the right skills can make things worse and cost more.

Remember: When in doubt, consult a professional to protect your investment and ensure safe, effective repairs.

Getting a pro to inspect your machine can save you time, money, and safety risks. While DIY is useful for some things, complex repairs need special skills and tools.

Preventive Maintenance Tips for Drum Longevity

Keeping your washing machine drum in good shape is key. Regular care can make your appliance last longer and save you money. It’s not hard, but it does need consistent effort and smart steps.

Start by stopping problems before they start. Here are some ways to keep your washing machine in top shape.

Regular Cleaning Routines

Keeping the drum clean is vital for its performance. Here are some cleaning tips:

- Run monthly hot water cleaning cycles

- Use specialized washing machine cleaners

- Wipe down drum and door seal after each use

- Remove lint and debris after every load

Load Balance Guidelines

How you load your washing machine matters a lot. Here’s how to load it right:

| Load Type | Recommended Action |

|---|---|

| Heavy Items | Mix with lighter clothing |

| Single Large Items | Add smaller items for balance |

| Delicate Fabrics | Use gentle cycle, avoid overloading |

Weight Distribution Best Practices

Spread your laundry out to avoid stress on the drum. Uneven loads can cause damage and vibration.

- Spread items evenly around the drum

- Avoid washing single heavy items alone

- Use appropriate spin speeds

- Check manufacturer’s load recommendations

Follow these tips to keep your washing machine running well. This will help it last longer and save you money on repairs.

Conclusion

Knowing if your washing machine drum is broken is key to keeping it working well. Spotting early signs and taking care of your drum can save you money and make your machine last longer.

Regular checks are important to catch problems early. Listen for odd noises, look for damage, and notice how your machine acts. Some fixes you can do yourself, but serious issues need a pro.

Being proactive helps a lot. Simple steps like balancing loads, not overloading, and cleaning your machine often can help avoid drum damage. If you’re unsure, get expert help to keep your machine running right.

Prevention is cheaper than fixing or replacing. By staying alert and informed, you can keep your washing machine in great shape. This way, you avoid sudden breakdowns that mess up your routine.

FAQ

How can I tell if my washing machine drum is broken?

What causes grinding noises in a washing machine?

Can I repair a broken washing machine drum myself?

How can I prevent washing machine drum damage?

What are the signs of worn-out drum bearings?

How much does it cost to replace a washing machine drum?

How long should a washing machine drum last?

What causes a washing machine drum to become unbalanced?

Related Articles: